Solar rolls break record

CSIRO scientists have reported a new record efficiency for next-gen roll-to-roll printed solar cells.

CSIRO scientists have reported a new record efficiency for next-gen roll-to-roll printed solar cells.

Printed onto thin plastic films, this lightweight and flexible solar technology is intended to help meet the growing demand for renewable energy by expanding the boundaries of where solar cells can be used.

Where silicon solar panels are rigid and heavy, the printed solar cells are highly flexible and portable, meaning they can be deployed in previously unimaginable ways across urban construction, mining operations, emergency management, disaster relief, space, defence and personal electronics.

CSIRO’s Renewable Energy Systems Group Leader, Dr Anthony Chesman, says the latest achievement is the result of more than a decade’s research and development.

“CSIRO’s thin and light-weight solar cells are now on the cusp of emerging from the lab to create clean energy in the real world,” Dr Chesman said.

“We’ve solved several engineering problems to achieve record results across a large surface area of interconnected modules.

“Roll-to-roll printing allows for the solar cells to be manufactured on very long, continuous rolls of plastic, which can dramatically increase the rate of production.

“As these methods are already widely used in the printing industry, this makes their production more accessible for Australian manufacturers.

“The successful commercialisation of printed flexible solar cells has the potential to create significant economic and environmental benefits for Australia and the world."

The results were achieved in collaboration with researchers from the University of Cambridge, Monash University, the University of Sydney and the University of New South Wales, and have been published in the leading journal Nature Communications.

CSIRO Principal Research Scientist Dr Doojin Vak said that an automated system produced a comprehensive dataset that will pave the way to use machine learning in future research.

“We developed a system for rapidly producing and testing over ten thousand solar cells a day – something that would have been impossible to do manually,” Dr Vak said.

“This allowed us to identify the optimal settings for the various parameters in the roll-to-roll process and quickly pinpoint the conditions that deliver the best results,” he said.

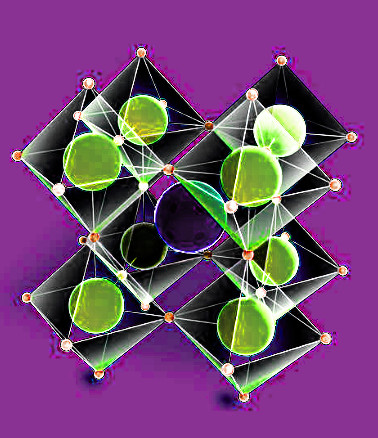

Incorporating an advanced material called perovskite, CSIRO’s printed solar is different from the silicon solar panels found on Australian roofs.

“Perovskites are a class of emerging solar cell material. They’re remarkable because they can be formulated into inks and used in industrial printers,” Dr Vak said.

“We've also alleviated the need to use expensive metals, such as gold, in their production by using specialised carbon inks, which further reduces production costs.”

Acknowledging that perovskite solar cells currently trail silicon solar panels in efficiency and lifetime when produced at scale, Dr Chesman sees the application of flexible panels to be very different.

“As these perovskite solar cells are printed onto plastic films, they are very lightweight, highly flexible and portable,” he said.

“The rigidity and weight of conventional silicon solar panels can make moving them difficult. Our thin, lightweight solar can be easily transported anywhere there is sun.

“We even sent the solar panels to space last week to test their performance, with a view to further optimise and ultimately provide a reliable energy source for future space endeavours.”

CSIRO says it is actively seeking industry partners to further develop and commercialise this technology.

Print

Print