Strength record for new print

Engineers have 3D-printed an impressive new titanium alloy.

Engineers have 3D-printed an impressive new titanium alloy.

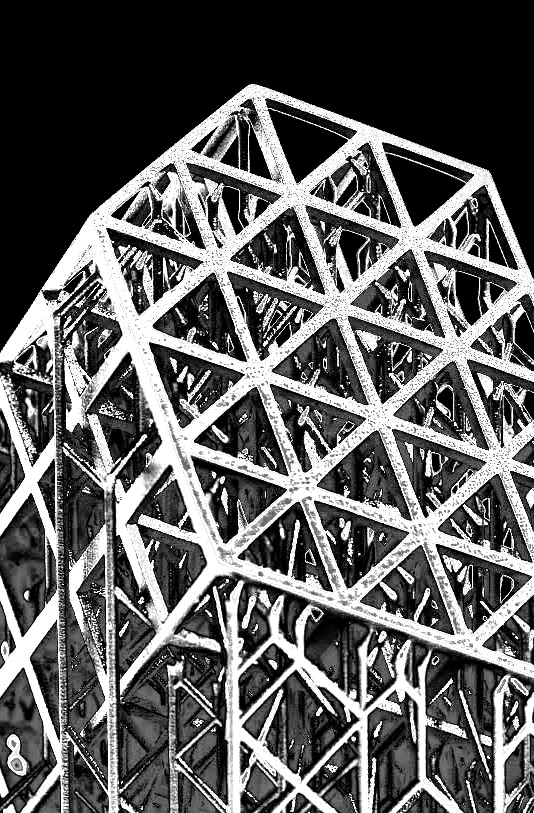

In a new demonstration, researchers have demonstrated how cutting-edge 3D-printing techniques can be used to produce an ultra strong commercial titanium alloy - a significant leap forward for the aerospace, space, defence, energy and biomedical industries.

A team at Monash University used a 3D-printing method to manipulate a novel microstructure. In doing so, they achieved unprecedented mechanical performance.

The research was undertaken on commercially available alloys and can be applied immediately, the team says.

Titanium alloys are presently the leading 3D-printed metal components for the aerospace industry.

However, most commercially available titanium alloys made by 3D-printing do not have satisfactory properties for many structural applications, especially their inadequate strength at room and elevated temperatures under harsh service conditions.

The researchers were able to exploit unique additive manufacturing processes to create ultrastrong and thermally stable parts in commercial titanium alloys, which could be directly implemented in service.

After a simple post-heat treatment on a commercial titanium alloy, adequate elongation and tensile strengths over 1,600 MPa were achieved, the highest specific strength among all 3D-printed metal to date.

This work paves the way to fabricate structural materials with unique microstructures and excellent properties for broad applications.

“Our findings offer a completely new approach to precipitation strengthening in commercial alloys that can be utilised to produce real components with complex shape for load-bearing application. This application is still absent for any Titanium alloys to date,” says Professor Aijun Huang.

“The 3D-printing plus simple heat treatment also means the process cost is greatly reduced compared to other materials with similar strength.”

More details are accessible here.

Print

Print