CSIRO scrubs for beer

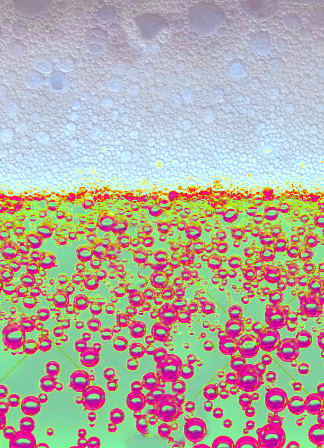

CSIRO has found a way to pull carbon dioxide (CO2) out of the atmosphere and put it into beer.

CSIRO has found a way to pull carbon dioxide (CO2) out of the atmosphere and put it into beer.

At a time when CO2 levels in the atmosphere are increasing, there have been shortages in industrial supplies of the gas over the past decade, impacting on fizzy beverage supply and food production.

Asutralia’s top science agency has now unveiled a new technology called Airthena, which was developed in partnership with Monash University, Energy Infrastructure and Resources and H2H Energy.

It draws on recent breakthroughs in advanced filtration methods to solve challenges around the water-food-energy nexus including sustainable resources, and environmental value and resilience.

Airthena captures CO2 directly from the air using tiny sponges known as metal-organic frameworks (MOFs), and can be scaled up for commercial production.

“As it requires just air and electricity to work, Airthena offers a cost-effective, efficient, and environmentally-friendly option to recycle CO2 for use on-site, on-demand,” said CSIRO project lead, Aaron Thornton.

“It also provides a more reliable source of CO2 for use in small-scale applications ranging from beverage carbonation to controlling pH in swimming pools, and industrial cleaning.”

A common method companies currently use to generate CO2 onsite relies on burning natural gas, which is subject to market price and supply fluctuations.

CO2 can also be bought from a supplier, which can involve expensive long-distance transportation and be prone to shortages.

Airthena only needs about two kilowatt-hours of electricity per kilogram of CO2, equal to around 20 cents per kilogram at minimum solar energy prices of $0.1 per kilowatt-hour at its current scale.

Airthena is capable of capturing two tonnes of CO2 from the atmosphere a year, making it suitable for small-scale applications right now, but Dr Thornton says it is scalable.

Print

Print