Big buzz around sound building

Engineers are using high-frequency sound waves can be used to build new materials.

Engineers are using high-frequency sound waves can be used to build new materials.

High frequency sound waves could revolutionise the field of ultrasound-driven chemistry, with a new review revealing the bizarre effects of these sound waves on materials and cells.

Demonstrations so far have shown molecules that seem to spontaneously order themselves after being hit with the sonic equivalent of a semi-trailer.

RMIT researchers have come up with a list of exciting applications of their work, including:

- Drug delivery to the lungs – patented nebulisation technology that could deliver life-saving drugs and vaccines by inhalation, rather than through injections

- Drug-protecting nanoparticles – encapsulating drugs in special nano-coatings to protect them from deterioration, control their release over time and ensure they precisely target the right places in the body like tumours or infections

- Breakthrough smart materials – sustainable production of super-porous nanomaterials that can be used to store, separate, release, protect almost anything

- Nano-manufacturing 2D materials – precise, cost-effective and fast exfoliation of atomically-thin quantum dots and nanosheets

“When we couple high-frequency sound waves into fluids, materials and cells, the effects are extraordinary,” says Distinguished Professor Leslie Yeo.

“We’ve harnessed the power of these sound waves to develop innovative biomedical technologies and to synthesise advanced materials.

“But our discoveries have also changed our fundamental understanding of ultrasound-driven chemistry - and revealed how little we really know.

“Trying to explain the science of what we see and then applying that to solve practical problems is a big and exciting challenge.”

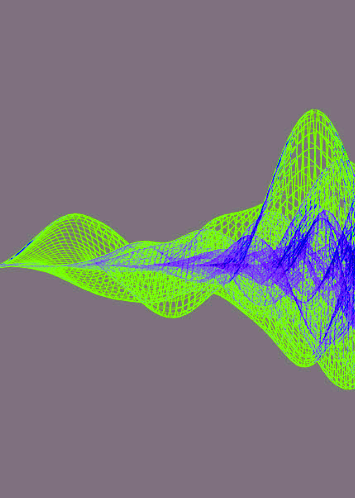

The team has been generating high-frequency sound waves on a microchip to precisely manipulate fluids or materials.

Ultrasound has long been used at low frequencies – around 10 kHz to 3 MHz – to drive chemical reactions, a field known as “sonochemistry”.

At these low frequencies, sonochemical reactions are driven by the violent implosion of air bubbles.

This process, known as cavitation, results in huge pressures and ultra-high temperatures – like a tiny and extremely localised pressure cooker.

But it turns out that if you increase the frequency, these reactions change completely.

When high frequency sound waves were transmitted into various materials and cells, the researchers saw behaviour that had never been observed with low-frequency ultrasound.

“We’ve seen self-ordering molecules that seem to orient themselves in the crystal along the direction of the sound waves,” Prof Yeo says.

“The sound wavelengths involved can be over 100,000 times larger than an individual molecule, so it’s incredibly puzzling how something so tiny can be precisely manipulated with something so big.

“It’s like driving a truck through a random scattering of Lego bricks, then finding those pieces stack nicely on top of each other – it shouldn’t happen.”

The RMIT team ais now focused on scaling up the technology.

At a low cost of just $US0.70 per device, the sound wave-generating microchips can be produced using the standard processes for mass fabrication of silicon chips for computers.

“This opens the possibility of producing industrial quantities of materials with these sound waves through massive parallelisation – using thousands of our chips simultaneously,” Prof Yeo said.

Print

Print