Gold sheets improve implants

A thin, flexible gold sensor has the potential to unlock the next generation of implantable medical devices.

A thin, flexible gold sensor has the potential to unlock the next generation of implantable medical devices.

Using a brand-new engineering method, researchers at UQ’s Australian Institute for Bioengineering and Nanotechnology (AIBN) were able to produce a small film-like sensor that is both flexible and sensitive enough to enable more streamlined future for electronic medical implants and real-time sensing applications.

The intricate approach used by Dr Mostafa Kamal Masud and PhD candidate Aditya Ashok represents a breakthrough in the field of flexible nanoarchitecture and, ultimately, suggests a new way to miniaturise and improve medical devices for diagnostics, biological sensing, and neurological exploration.

“Although modern implanted electronics have developed rapidly over the past 60 years, most commercially available devices are still built on relatively similar – and limiting - design concepts such as thick ceramic or titanium packaging,” said Dr Masud.

“We are offering a new route toward miniaturised, flexible, implanted medical devices that will diagnose and treat chronic diseases and help improve the lives of millions of people.”

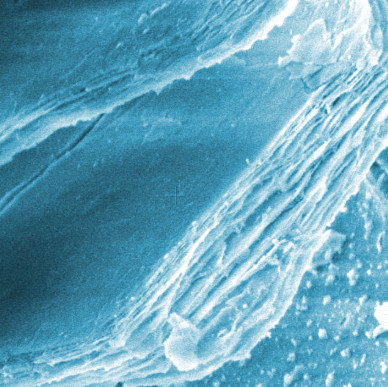

The film-like sensor designed by Dr Masud and Mr Ashok represents a novel approach to the field of mesoporous materials, which are highly porous substances with traits that benefit diagnostics, catalysis, and drug delivery.

Using a novel hybrid fabrication process, the team was able to synthesise a mesoporous gold film that acts as an electrode for biosensing and bioimplant applications.

The flexibility and sensitivity of the gold film make it an ideal wearable system for real-time monitoring of body glucose, while Dr Masud said there was strong potential for implanted nerve recording applications.

“The demand for a simple and robust fabrication process with this kind of flexible electronics is enormous,” Dr Masud said.

“Our aim here is to see this sensor embedded in wearable devices – but the potential and possibilities in this field are vast. We’re going to be exploring more in our coming projects.”

The research has been published in the journal Small.

Print

Print