Evolving light box blocks better range on command

Engineers have used a genetic approach to create a material that can protect against electromagnetic radiation over a wide range of wavelengths.

Engineers have used a genetic approach to create a material that can protect against electromagnetic radiation over a wide range of wavelengths.

The specially-formed material can provide custom broadband absorption in the infrared range.

The design was identified using “genetic algorithms”, according to engineers from Penn State in the US.

The new metamaterial can shield objects from view by infrared sensors, protect instruments and be manufactured to cover a variety of wavelengths.

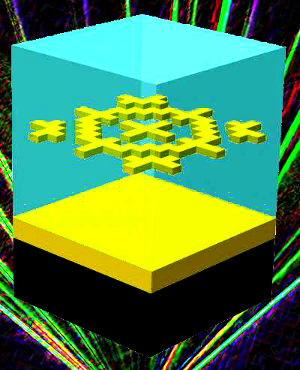

It is made of several layers on a silicon base.

The first layer is palladium, followed by a polyimide layer. On top of this plastic layer is a palladium screen layer. The screen has elaborate, complicated cutouts - sub wavelength geometry - that serve to block the various wavelengths. A polyimide layer caps the whole absorber.

“As long as the properly-designed pattern in the screen is much smaller than the wavelength, the material can work effectively as an absorber,” said Lan Lin, graduate student in electrical engineering.

“It can also absorb 90 percent of the infrared radiation that comes in at up to a 55 degree angle to the screen.”

To lay out the necessary screen, researchers copied the approach that genes use to mutate their way toward an effective design.

They described the screen pattern by a series of zeros and ones - a chromosome - and let an algorithm randomly select patterns to create an initial population of candidate designs.

The algorithm then tested the patterns and eliminated all but the best.

The best patterns were then randomly tweaked for the second generation. Again the algorithm discarded the worst and kept the best.

After a number of generations the patterns met and even exceeded the design goals. Along the way the best pattern from each generation was retained.

“We wouldn't be able to get an octave bandwidth coverage without the genetic algorithm,” said Jeremy A. Bossard, postdoctoral fellow in electrical engineering.

“In the past, researchers have tried to cover the bandwidth using multiple layers, but multiple layers were difficult to manufacture and register properly.”

This evolved metamaterial can be easily manufactured because it is simply layers of metal or plastic that do not need complex alignment.

The clear cap of polyimide serves to protect the screen, but also helps reduce any impedance mismatch that might occur when the wave moves from the air into the device.

“Genetic algorithms are used in electromagnetics, but we are at the forefront of using this method to design metamaterials,” said Bossard.

The results are reported in a recent issue of ACS Nano.

Print

Print