CPUs used to improve clockwork

High-tech methods have been used to improve centuries-old clockwork mechanisms.

High-tech methods have been used to improve centuries-old clockwork mechanisms.

An international team of computer scientists have developed a new computational system to aid the design and fabrication of wind-up toys, focusing on automating the intricate interior machinery responsible for the toys' wind-up motion.

The system includes analytic modelling of the elemental mechanisms found in common wide-up toys, including their geometry and kinematics, to aid the construction of toys with moving parts that consume less energy.

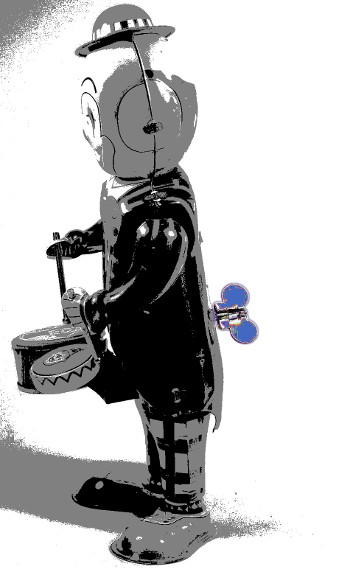

Wind-up toys are typically lightweight with compact internal mechanical assemblies that are powered by clockwork motors attached to a spring key.

Once the toy is wound up and the interior spring is released, the stored potential energy drives the toy's internal mechanical parts, which then prompts the additional parts of the toy to perform their specified motions, like swinging arms, a moving tail, a bobbing head, for example.

The interior assembly often consists of small mechanical parts of nontrivial shapes.

These parts have to compactly stay within the toy's body shell and connect to each other with minimal friction for efficient motion transfer, making wind-up toys difficult to design manually.

“In the era of personalised fabrication like 3-D printing, we asked, why can't novices still design customized wind-up toys?” asked lead researcher Dr Peng Song.

“We set out to computationally design these expressive toys with moving parts but requiring low energy.”

The researchers went over 11 elemental mechanisms commonly found in wind-up toys--fundamental motion patterns such as swinging while moving or bobbing up and down while bumping right to left - and modelled their geometry, kinematic properties, and connections.

Given user inputs such as toy parts, motion range and motor pose, the team's new method automatically constructs and arranges the mechanical parts inside the toy for delivering the desired toy motion.

The researchers optimised the geometry of the wind-up mechanism by aiming to compact the mechanism, minimize its weight, avoid collision between any internal parts with the spring motor and body shell, and assure the desired motion of the toy is achieved.

Even people with no experience in clockwork design were able to successfully design their own wind-up toys using the new computational system.

The designs were 3-D printed to test the functionality of the new model.

Using a wind-up toy teapot as an example, the researchers showed that their computer-aided design resulted in a more compact mechanism with smaller mechanical parts, and the ability to run motions for longer durations and move over a longer distance.

Down the road, the researchers plan to explore the use of their methods on micro-robot design and mechanical toys that run on limited battery power.

A demonstration can be seen in the video below.

Print

Print